About NORM

Designed to safely manage, treat, and responsibly dispose of NORM generated during exploration and production activities by ADNOC Operating Companies (OPCOs), the NORM plant is the first facility in the world to combine all Naturally Occurring Radioactive Materials’ treatment units and disposal in one facility.

With a capacity of 6.5 KTA, this facility incorporates a high-pressure water descaling system, incineration processes, and encapsulation of ashes to ensure the proper treatment and disposal of NORM waste.

NORM has implemented automated systems that help eliminate the need for manual handling of potentially hazardous materials, significantly reducing the radiation exposure risk of workers in operation.

This facility has been established in compliance with the ‘Federal Authority for Nuclear Regulation’ (FANR) following the International Atomic Energy Agency (IAEA), “Radiation Protection and the Management of Radioactive Waste in the Oil and Gas Industry”.

Our Process

Descaling

Clearance Unit

Advanced decontamination techniques are employed to ensure that tubulars, such as pipes or drill strings, are safe for reuse or disposal. The goal is to minimize the generation of secondary waste while ensuring safety for personnel and the environment.

Waste Pre-conditioning & Sludge Centrifuge

Sludge drums are emptied according to their contents and stored in reaction tank and sludge silo.

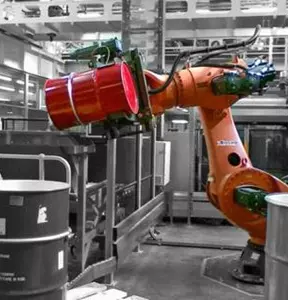

An automatic elevator and tilter (Kuka Robotic Arm) is used to handle drum movement. With the primary goal of reducing human involvement in the pre-conditioning phase, this robot system is programmed to systematically select and handle each drum in a pre-determined sequence. The arm's task is to carefully tilt each drum, pouring its contents into a hopper designed for centrifugal separation. This separation process effectively divides liquids from the sludge.

The solid and liquid phases are then separated from preconditioned sludge by using a centrifugal decanter

Incineration

The NORM-contaminated scale, sludge, recovered oil, water and burnable miscellaneous materials are thermally destroyed and converted into ashes, flue gas and heat. This operation's main purpose is to reduce the volume and weight of different types of NORM waste.

Stabilization & Solidification

The ashes are then prepared for its final disposal. A first mixer allows the ashes to be chemically stabilized, while a second mixer allows the ashes to be encapsulated in concrete.

Through this process, radioactive waste is converted into a physically and chemically stable product which can be considered less hazardous to the environment.

Engineered Landfill

NORM's engineered landfills are designed specifically for the disposal of naturally occurring radioactive material (NORM) waste, following strict US-EPA standards. The construction methods and materials used, such as high-density polyethylene (HDPE) liners, are chosen to ensure long-term containment and integrity of the landfill.

Before NORM waste can be disposed of in these engineered landfills, it must undergo rigorous testing, as outlined in the USEPA SW-846 Method 1311 (TCLP) and NORM's Waste Transfer Protocol. It is the responsibility of the group companies (GCs) to analyze and classify the waste accurately before transporting it to the NORM facility.

Stabilized NORM waste is directly deposited into the landfill cells. Any liquid that percolates through the waste, known as leachate, is captured by the impermeable HDPE liner system, which prevents it from contaminating the surrounding environment. This leachate is then collected and treated on-site to further ensure safety.

The landfill is managed by a team of highly skilled professionals who maintain optimal operation standards, adhering to international guidelines and best practices for environmental protection and public safety.